- Need Free Consultation ?

(+86) 13145896507

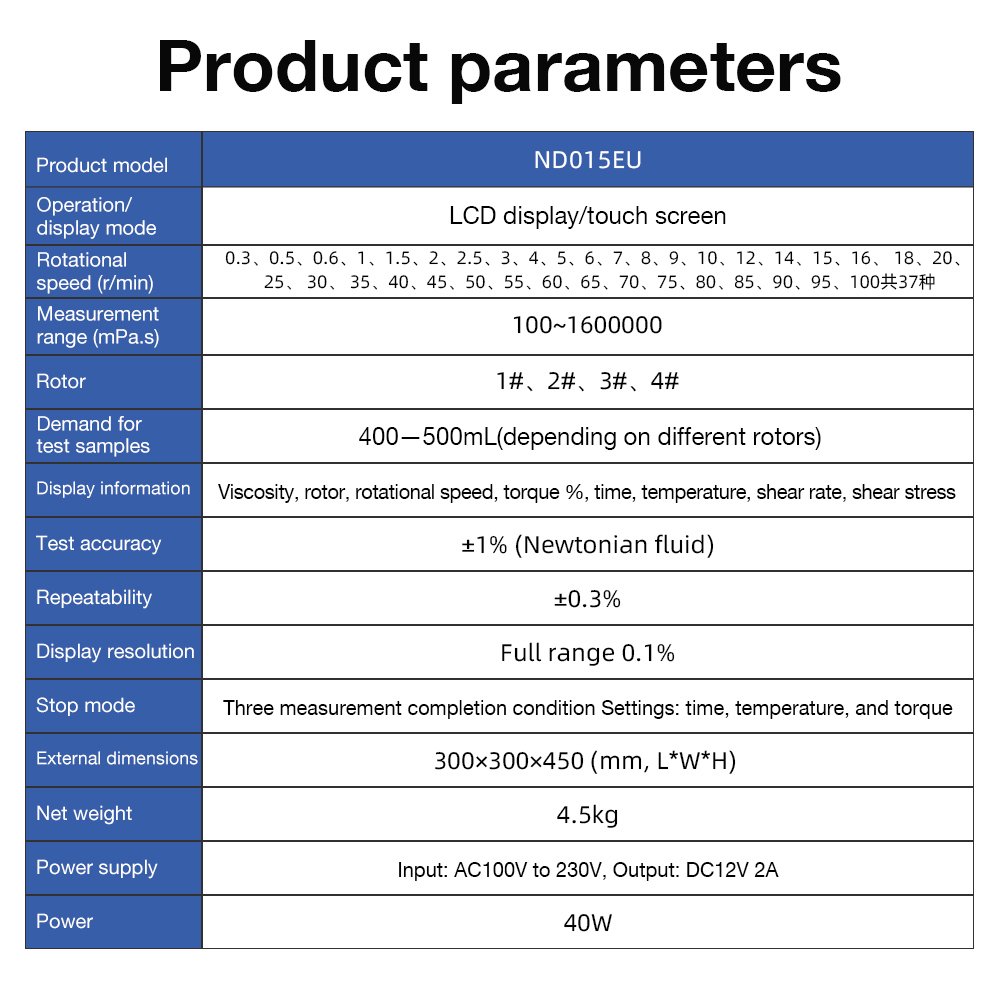

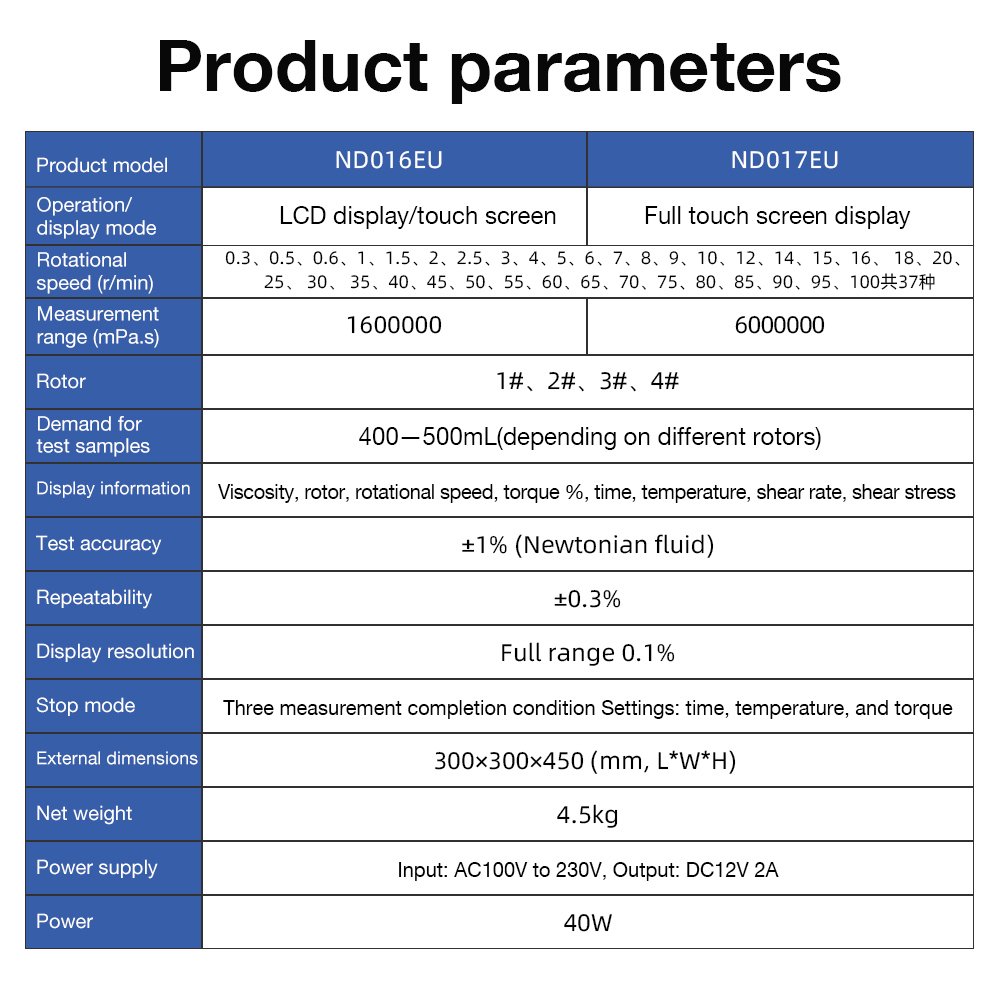

ND011/ND012/ND015/ND016/ND021/ND022

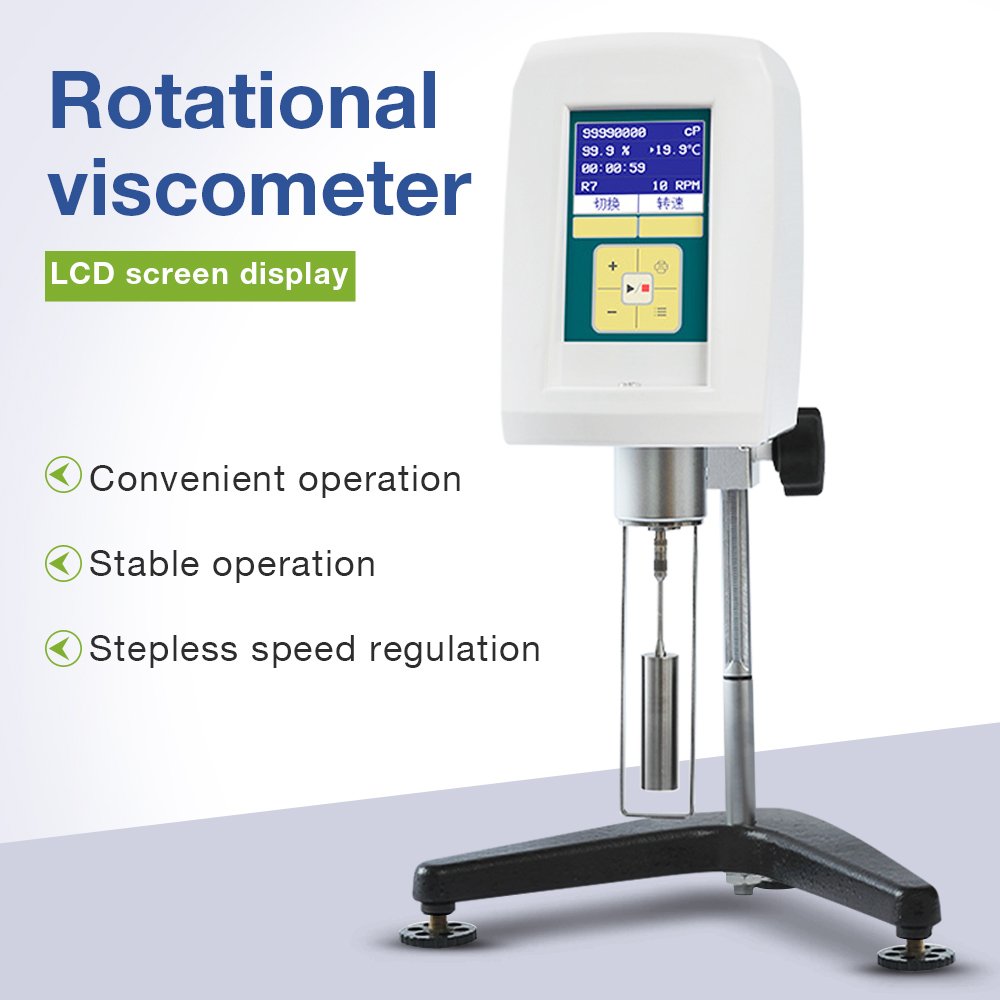

Rotational viscometer is a precision instrument used to measure the viscosity of fluids by determining the torque required to rotate a spindle immersed in the sample. It operates based on the principle that a fluid’s resistance to flow (viscosity) creates drag on the spindle, which is proportional to the applied rotational speed.

There are two main types: controlled-rate (applies rotation and measures torque) and controlled-stress (applies torque and measures rotation). Common designs include cone-and-plate, parallel-plate, and cylinder (Couette) systems, ensuring accurate shear rate control for Newtonian and non-Newtonian fluids.

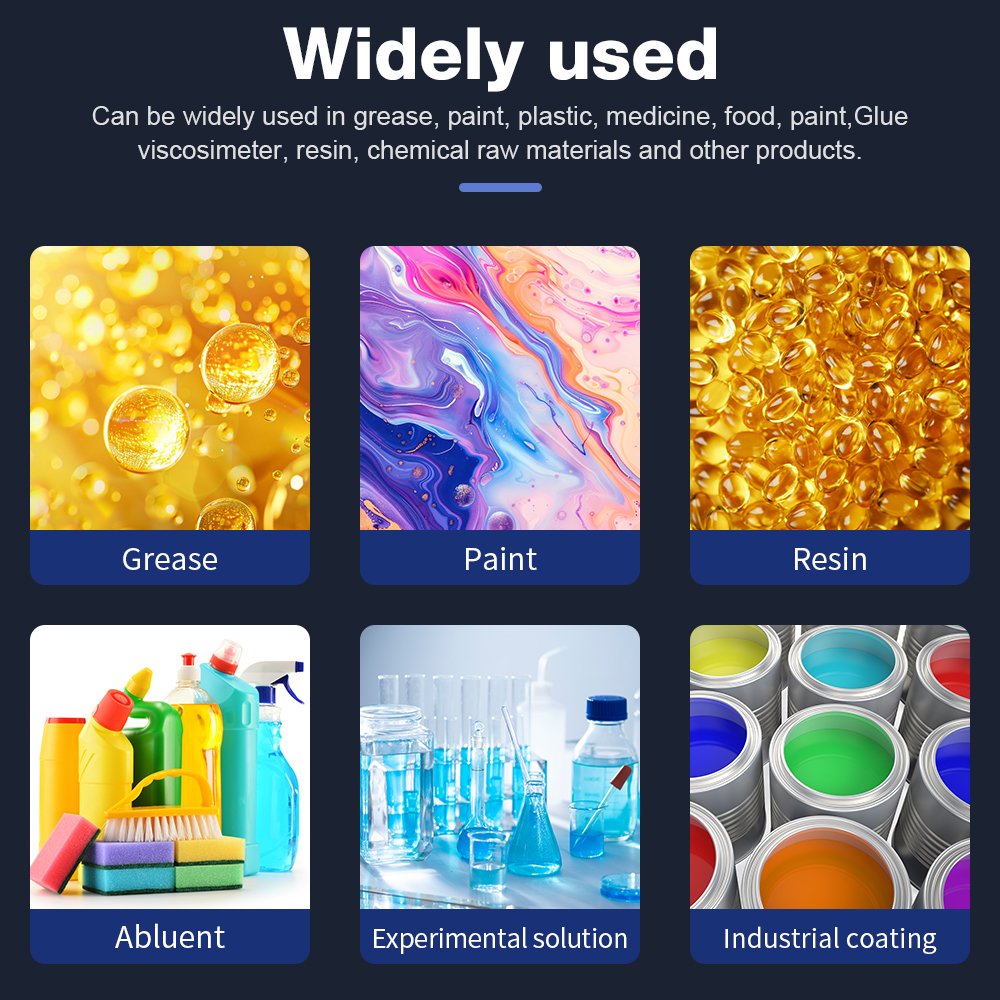

Key advantages include wide viscosity range detection, shear rate adjustability, and temperature control for consistent results. Applications span industries like food, cosmetics, pharmaceuticals, paints, and petroleum, where viscosity affects product quality.

Modern rotational viscometers feature digital interfaces, automated calibration, and data analysis software, enhancing precision and efficiency. By providing reliable viscosity data, they optimize formulations, ensure process stability.

In summary, rotational viscometers are vital for fluid analysis, combining mechanical innovation with advanced technology to deliver accurate, repeatable measurements.

“Excellent communication, high quality product. Timely delivery. I have been cooperating for 2 years and am satisfied with the established cooperation.”