- Need Free Consultation ?

(+86) 13145896507

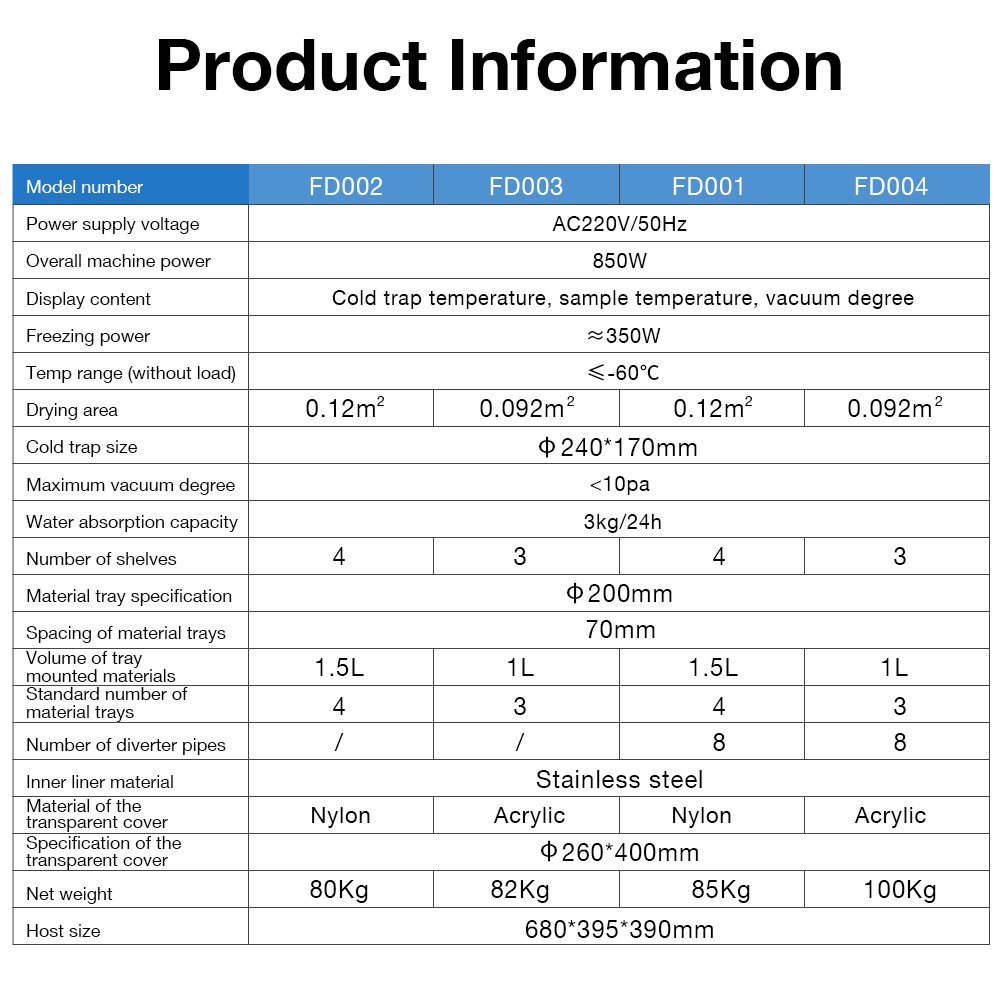

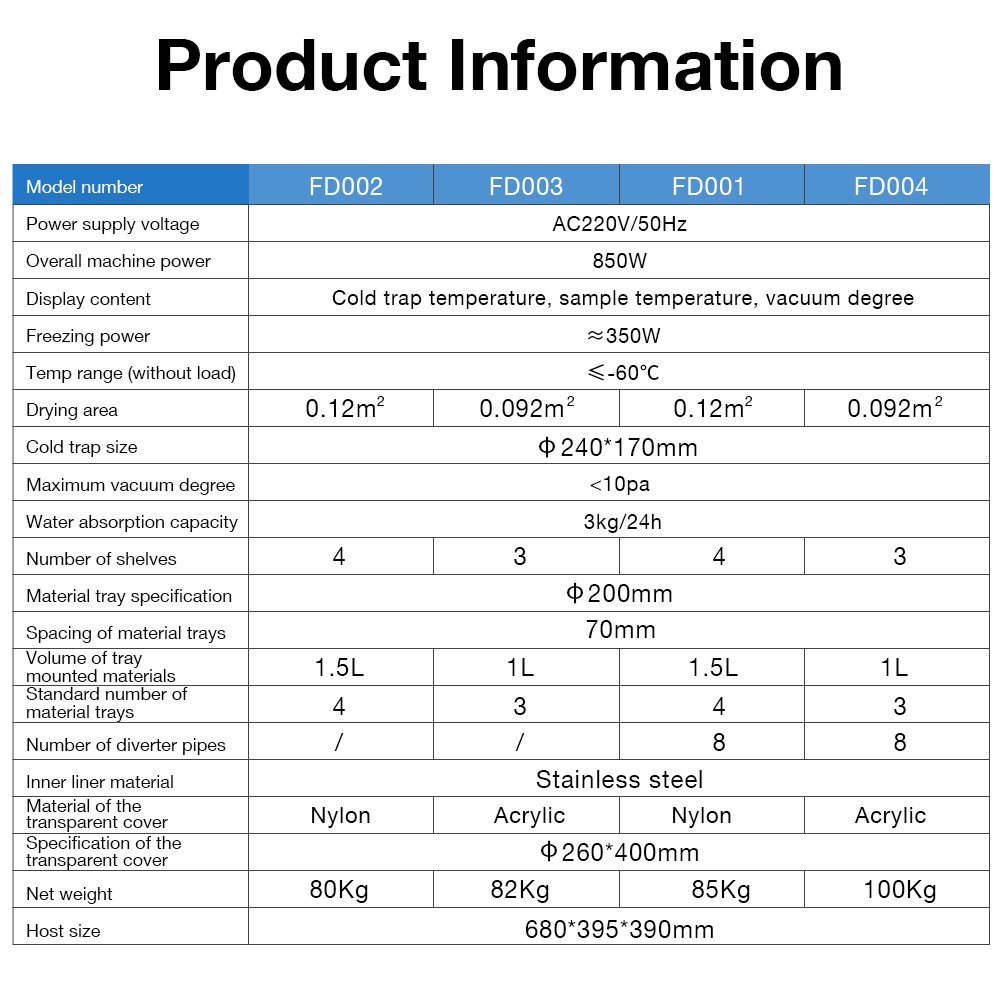

FD001/FD002/FD003/FD004

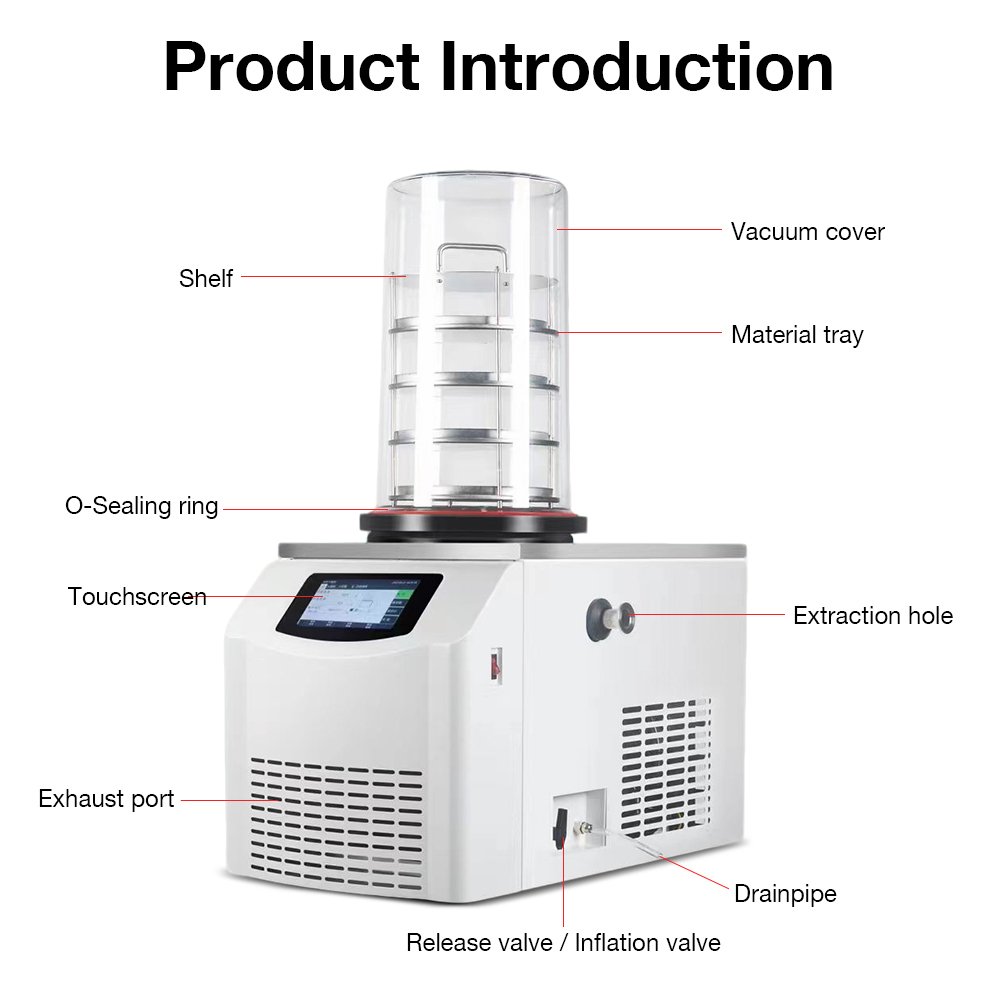

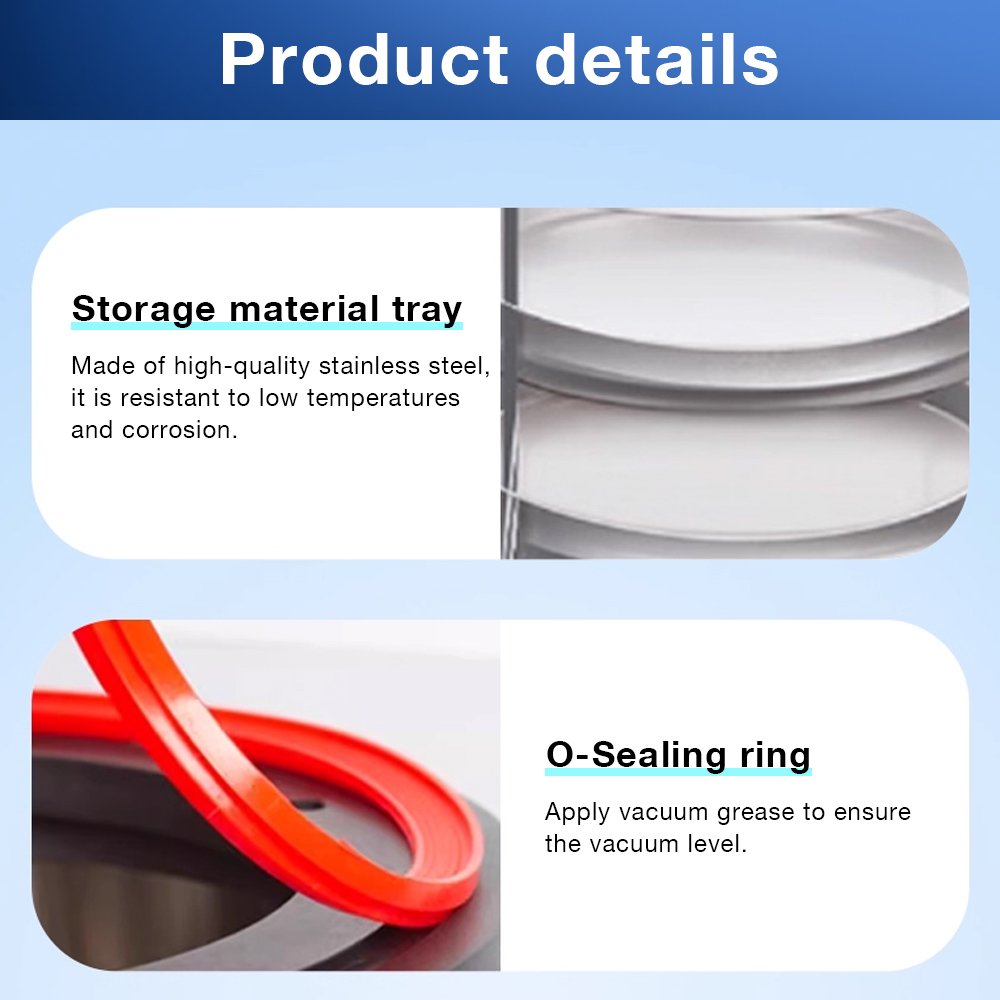

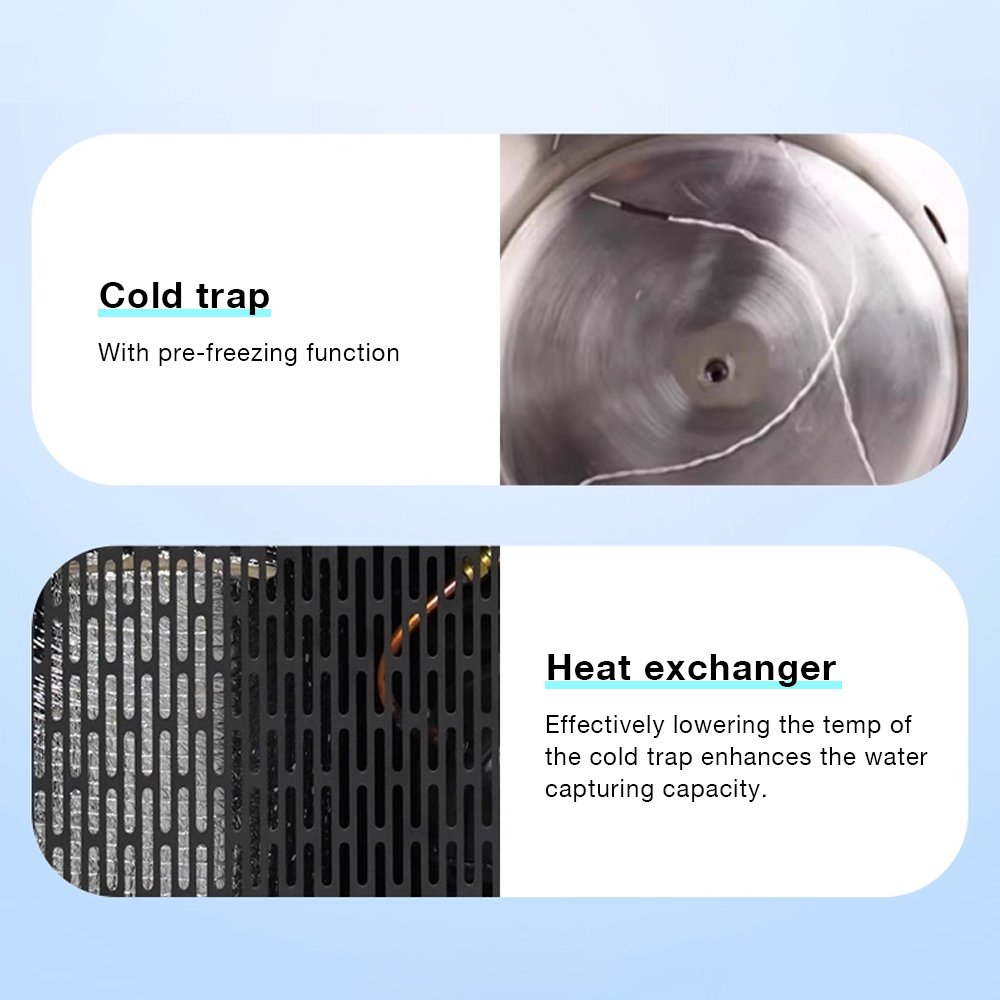

The -60°C Vacuum Freeze Dryer is an advanced dehydration system designed to preserve sensitive materials by removing moisture under low-temperature and vacuum conditions. It operates by first freezing the product to -60°C or below, solidifying all water content. A high vacuum is then applied, and controlled heat is introduced, allowing the frozen water to sublimate directly from ice to vapor without passing through a liquid phase. This process, called lyophilization, maintains the material’s original structure, biological activity, and chemical composition.

Key features include precise temperature control, a robust vacuum system, and condenser units capable of efficiently capturing vapor at extremely low temperatures. Its primary advantage is the exceptional preservation it offers, preventing damage from heat or crystallization that occurs in conventional drying.

This technology is vital across numerous fields. In pharmaceuticals, it is used to stabilize vaccines, antibodies, and antibiotics. In biotechnology and research, it preserves enzymes, microbial cultures, and sensitive reagents. The food industry employs it to create high-quality, shelf-stable ingredients while retaining nutrients, flavor, and aroma. It is also crucial for preserving historical documents and preparing specialized materials in nanotechnology and electronics.

In summary, the -60°C Vacuum Freeze Dryer is an indispensable tool for long-term stabilization of valuable, heat-sensitive products, ensuring maximum functionality and integrity upon reconstitution.

“Excellent communication, high quality product. Timely delivery. I have been cooperating for 2 years and am satisfied with the established cooperation.”