- Need Free Consultation ?

(+86) 13145896507

MF08

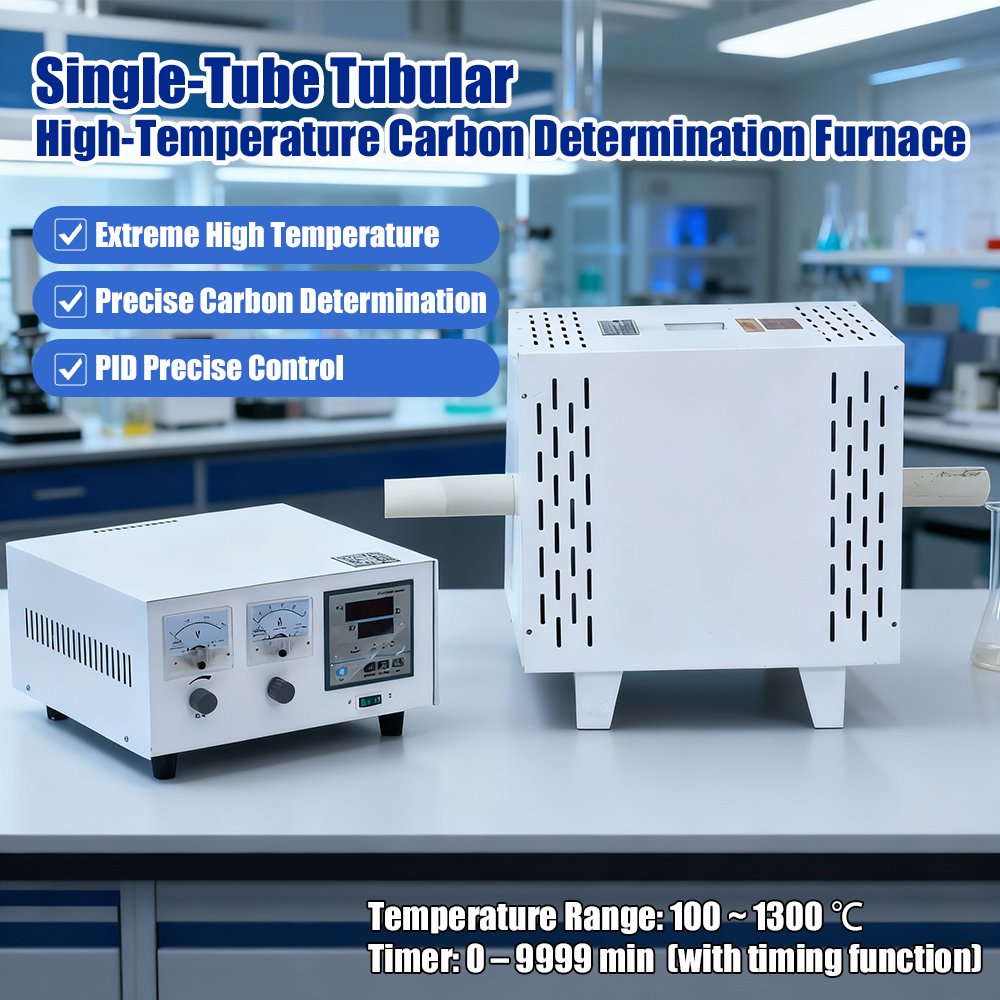

The 1300°C Single-Tube Tubular High-Temperature Carbon Determination Furnace is a precision laboratory instrument designed for the accurate analysis of carbon content in various materials, primarily metals, alloys, and inorganic solids. Its core function is to combust a sample at an extremely high temperature in a controlled oxygen-rich atmosphere, converting all carbon present into carbon dioxide (CO2) for subsequent quantitative measurement.

Constructed around a durable high-purity alumina or quartz tube, the furnace features a sophisticated electric heating system that ensures rapid heating and uniform temperature distribution up to 1300°C, a critical threshold for complete combustion of resistant carbides. Precise digital PID controllers maintain temperature stability essential for reproducible results.

Key operational components include a sample loading system, often a ceramic boat, which is introduced into the hot zone via a push rod. During analysis, oxygen is purged through the tube. The evolved gases are then swept into an associated detection system, such as an infrared absorption cell or a thermal conductivity detector, which precisely measures the CO2 concentration to calculate the carbon content.

This furnace is indispensable in metallurgy, foundries, quality control labs, and research institutions for applications like grade verification of steel and cast iron, certification of raw materials, and investigation of new alloys. Its single-tube design offers a robust, reliable, and user-friendly platform for fundamental carbon/sulfur determinators, providing vital data for material properties, process control, and compliance with industry standards.

“Excellent communication, high quality product. Timely delivery. I have been cooperating for 2 years and am satisfied with the established cooperation.”