- Need Free Consultation ?

(+86) 13145896507

LA088

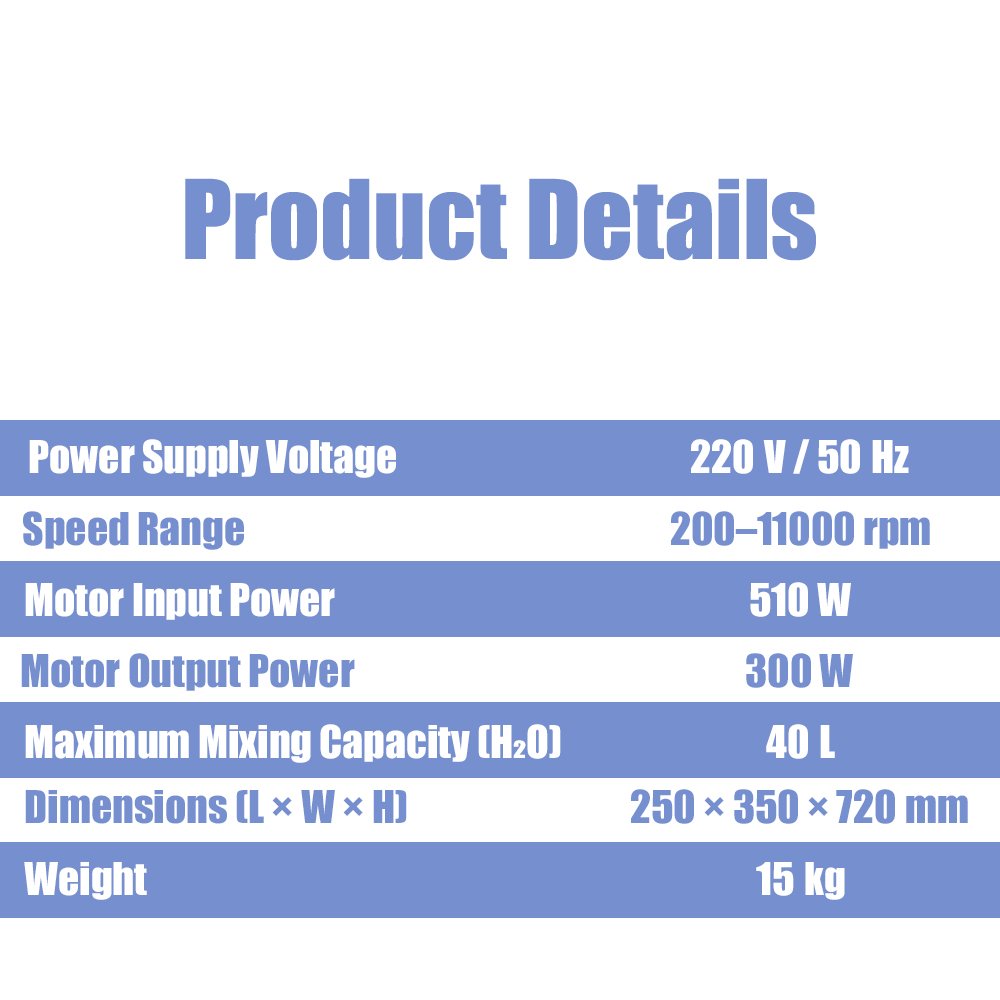

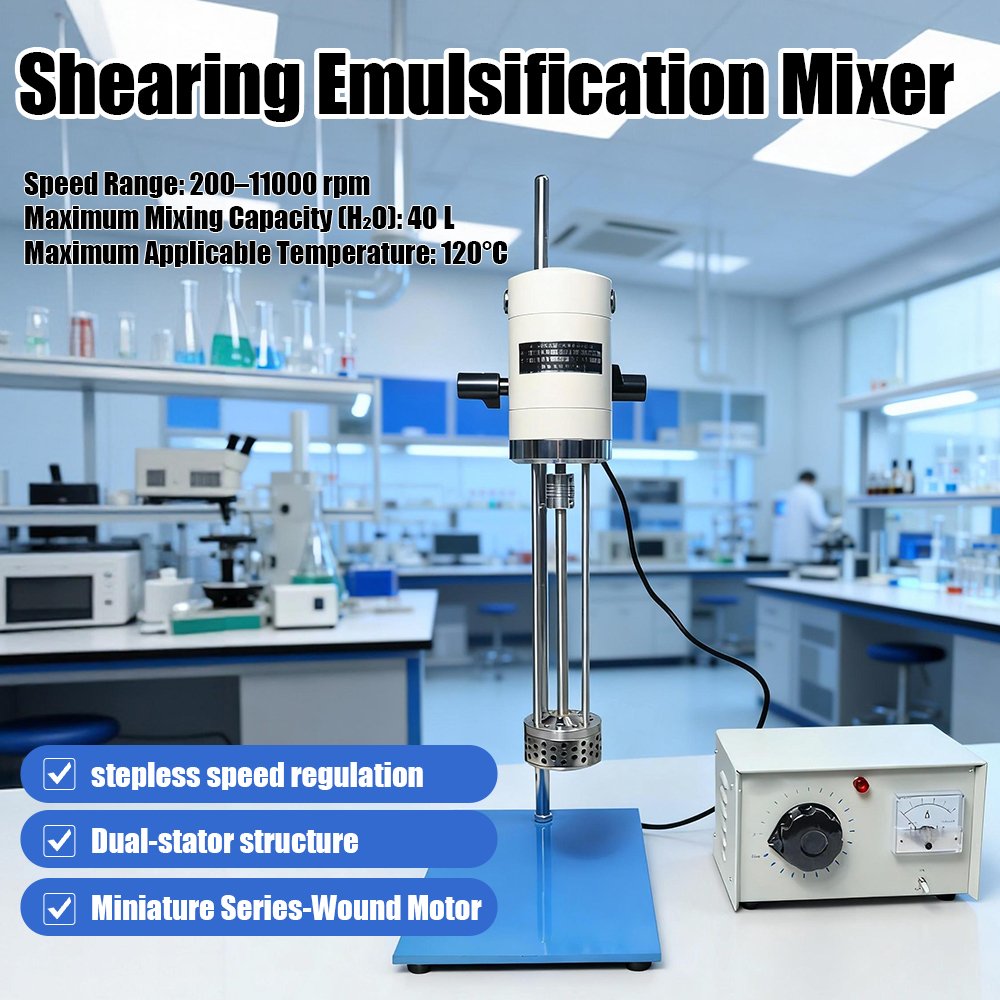

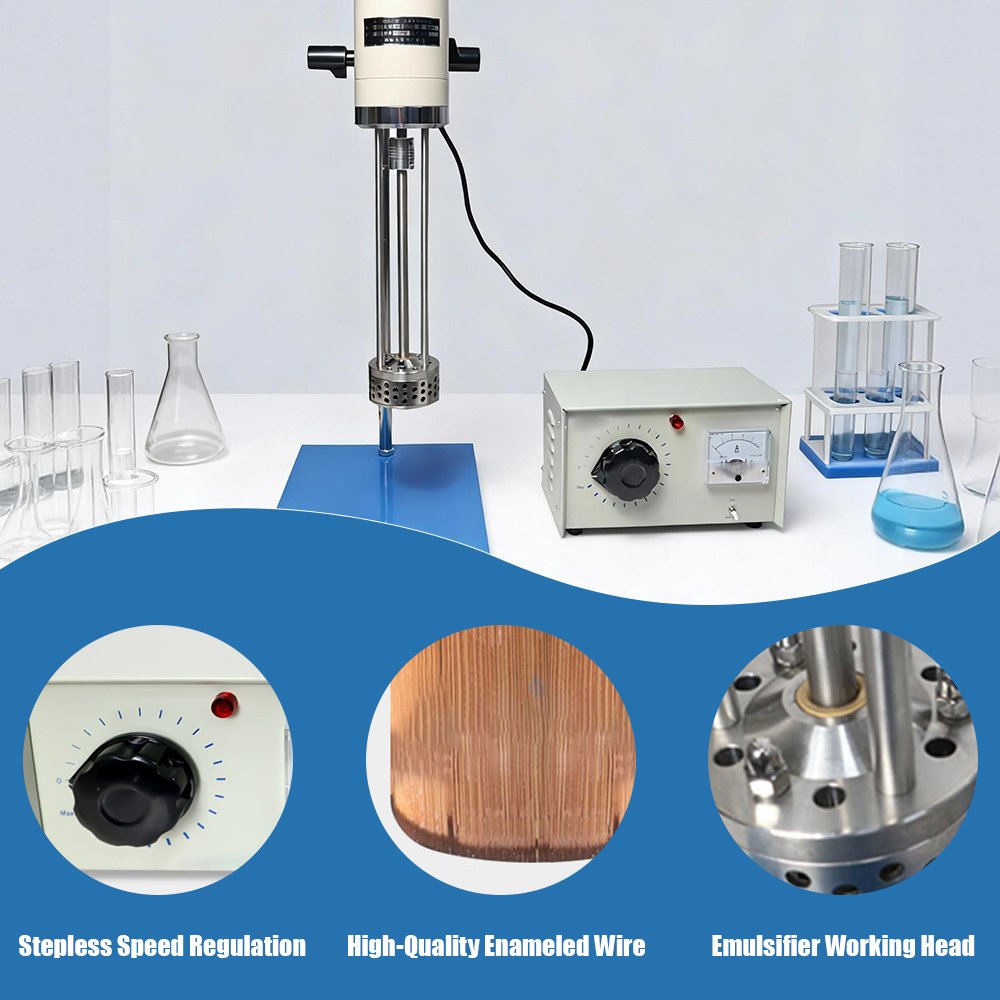

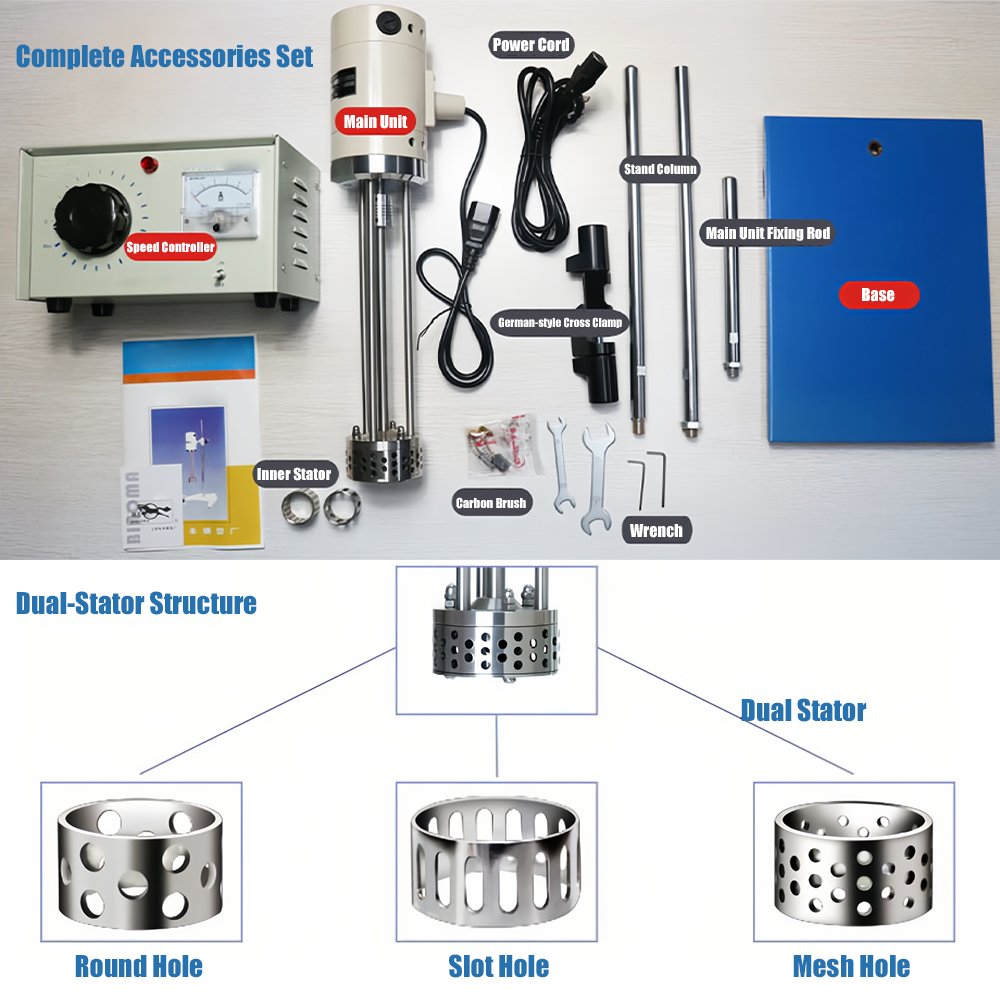

This high-shear emulsifier is an industrial machine designed to create stable, fine emulsions and dispersions by applying intense mechanical shear. At its core is a precision-engineered rotor-stator assembly. The high-speed rotor, working within a close-tolerance stator, generates tremendous suction, drawing materials into the mixing head. Here, they are subjected to extreme hydraulic shear, turbulent flow, and cavitation forces, reducing droplet or particle size to the micron or sub-micron level.

This intensive process ensures rapid, homogeneous mixing and the formation of a stable, uniform product with a long shelf life. Key advantages over conventional mixers include superior product consistency, significantly reduced processing time, and the ability to handle challenging formulations with high viscosity or solid content.

Modern high-shear emulsifiers are highly versatile, offering variable speed control, different rotor-stator generator heads for specific textures, and scalability from laboratory R&D to full industrial production. They are often configured as inline systems for continuous processing or batch units for complete vessel circulation.

These machines are indispensable across industries where product stability, texture, and consistency are critical. Primary applications include the manufacturing of cosmetics (creams, lotions), pharmaceuticals (ointments, syrups), food products (sauces, dressings), and chemicals (paints, lubricants). By delivering unmatched mixing efficiency and product quality, the high-shear emulsifier is a foundational technology for advanced manufacturing processes.

“Excellent communication, high quality product. Timely delivery. I have been cooperating for 2 years and am satisfied with the established cooperation.”