- Need Free Consultation ?

(+86) 13145896507

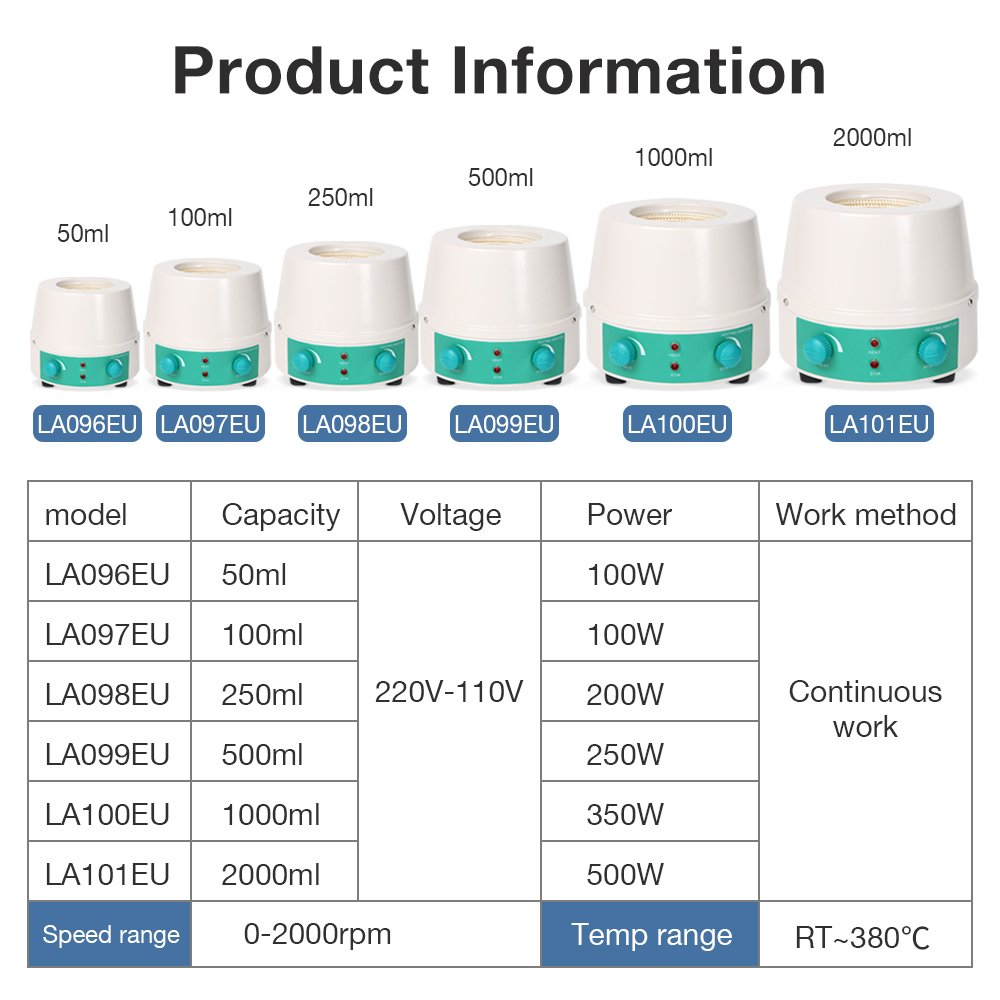

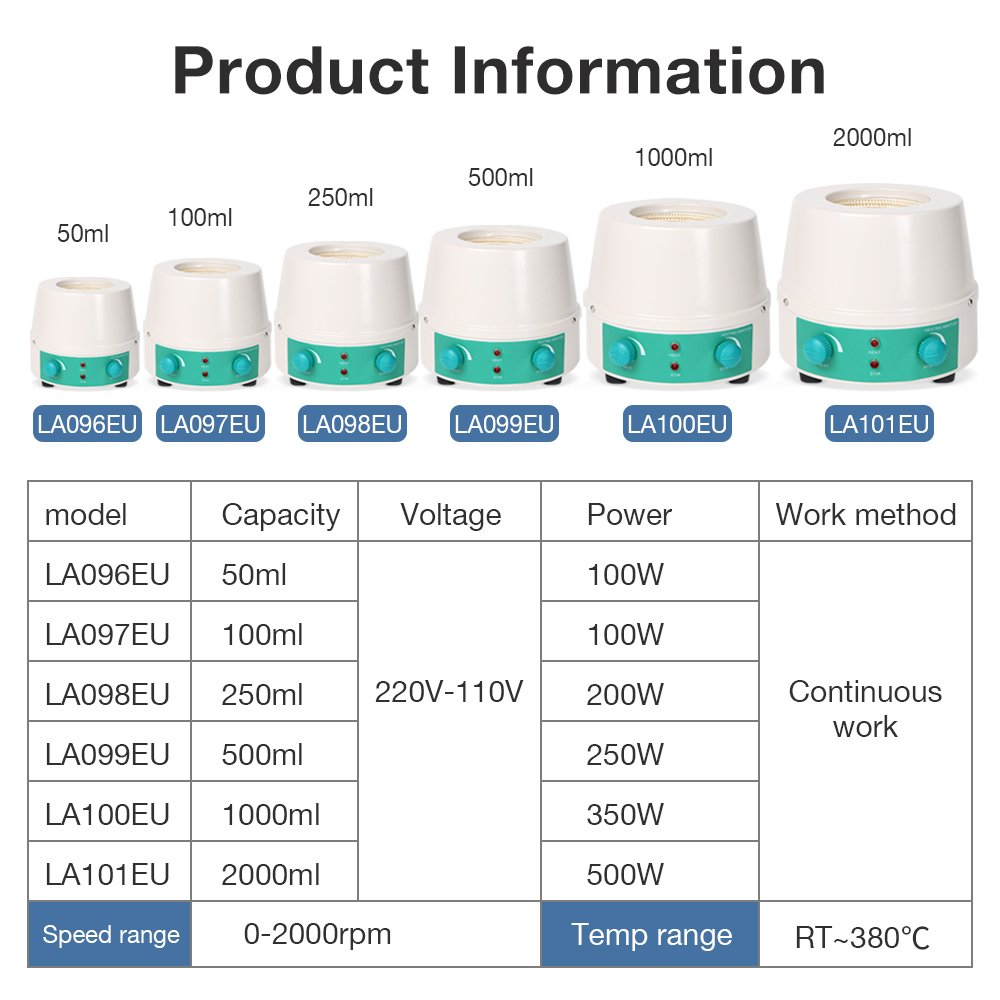

Electromagnetic Force Stirring Heating Jacket is an advanced heating device designed for precise temperature control and uniform heat distribution in industrial processes. Utilizing electromagnetic induction, it generates eddy currents within conductive materials, enabling efficient and rapid heating.

Key Features:

Electromagnetic Stirring: Combines heating with forced convection, ensuring homogeneous mixing and preventing material sedimentation or overheating.

Energy Efficiency: Direct energy transfer minimizes heat loss, reducing power consumption compared to traditional methods.

Precise Temperature Control: Equipped with sensors and automated systems for accurate regulation, ideal for sensitive applications like chemical reactions or food processing.

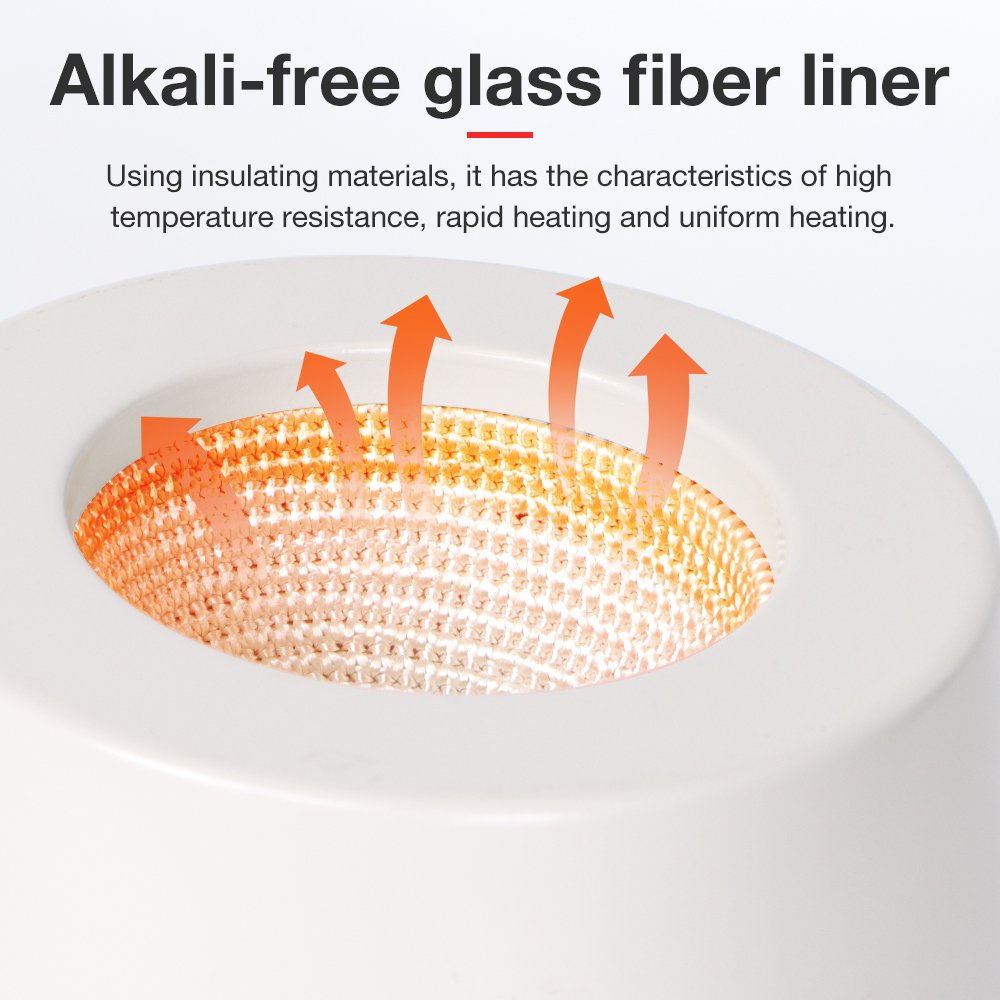

Uniform Heating: Eliminates hot spots, enhancing product quality in industries such as pharmaceuticals, metallurgy, and petrochemicals.

Durability & Safety: Robust construction with insulation layers prevents leaks and electromagnetic interference, ensuring operator safety.

Applications:

Widely used in reactors, pipelines, and storage tanks, this jacket is essential for processes requiring consistent heating and mixing, including polymerization, crystallization, and viscosity management.

By integrating electromagnetic stirring with heating, this technology boosts efficiency, reduces energy costs, and improves process reliability in diverse industrial sectors.

“Excellent communication, high quality product. Timely delivery. I have been cooperating for 2 years and am satisfied with the established cooperation.”