- Need Free Consultation ?

(+86) 13145896507

Hand-operated filling machine is a compact, manually-driven device designed for precise liquid or semi-liquid product dispensing into containers. It operates without electricity, utilizing a lever or piston mechanism controlled by the user.

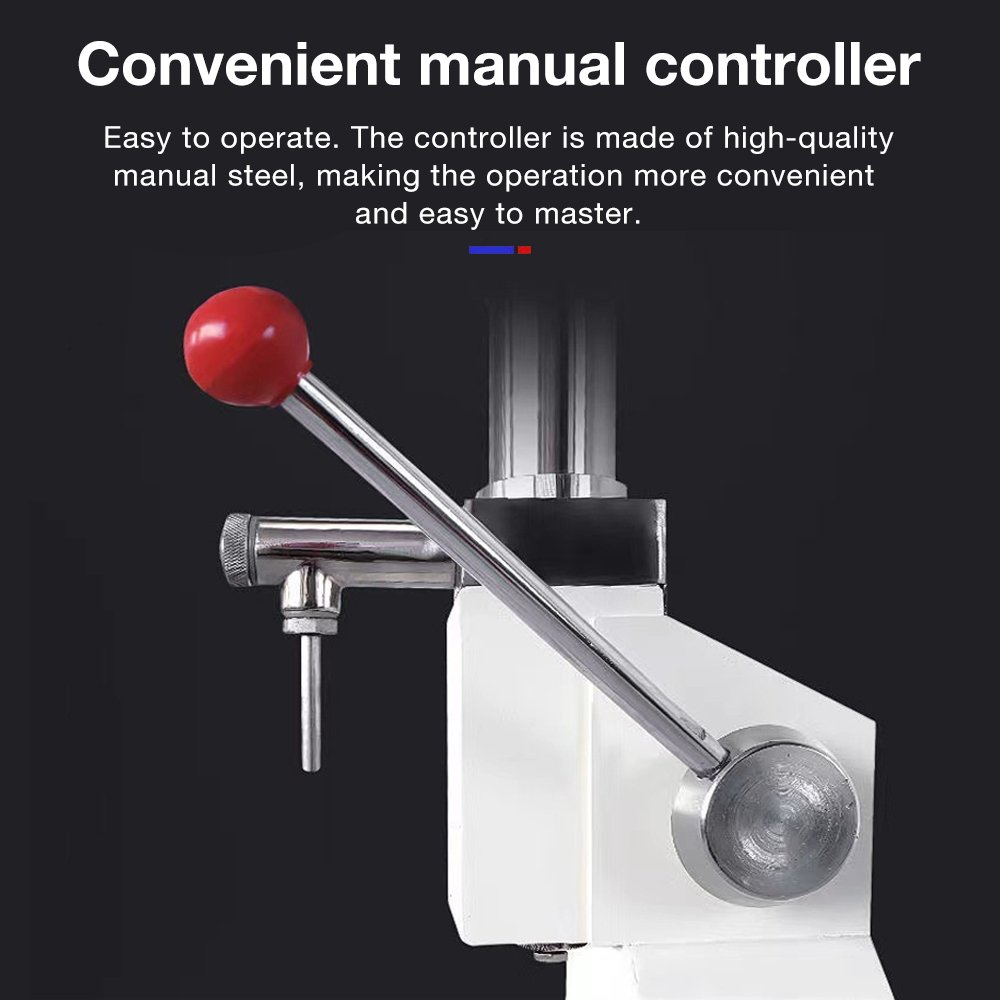

The core components typically include a storage tank, a dip tube for product intake, a calibrated piston or pump, and a dispensing nozzle. Operation is straightforward: the operator places an empty container under the nozzle, pulls the lever to draw the product from the tank into the pump chamber, and then pushes the lever to release a pre-measured amount through the nozzle into the container.

These machines are prized for their simplicity, portability, and low cost. They are ideal for low-volume production, small businesses, pilot batches, laboratories, or settings without reliable power. Common applications include filling bottles with water, juices, oils, sauces, honey, cosmetics like lotions, and light chemicals.

Key advantages are their affordability, minimal maintenance, easy cleaning, and ability to be used anywhere. The primary limitation is the reliance on manual labor, making them slower and less suitable for high-volume operations compared to automatic fillers. They offer an essential, efficient solution for basic, small-scale filling needs.

“Excellent communication, high quality product. Timely delivery. I have been cooperating for 2 years and am satisfied with the established cooperation.”