- Need Free Consultation ?

(+86) 13145896507

STP27

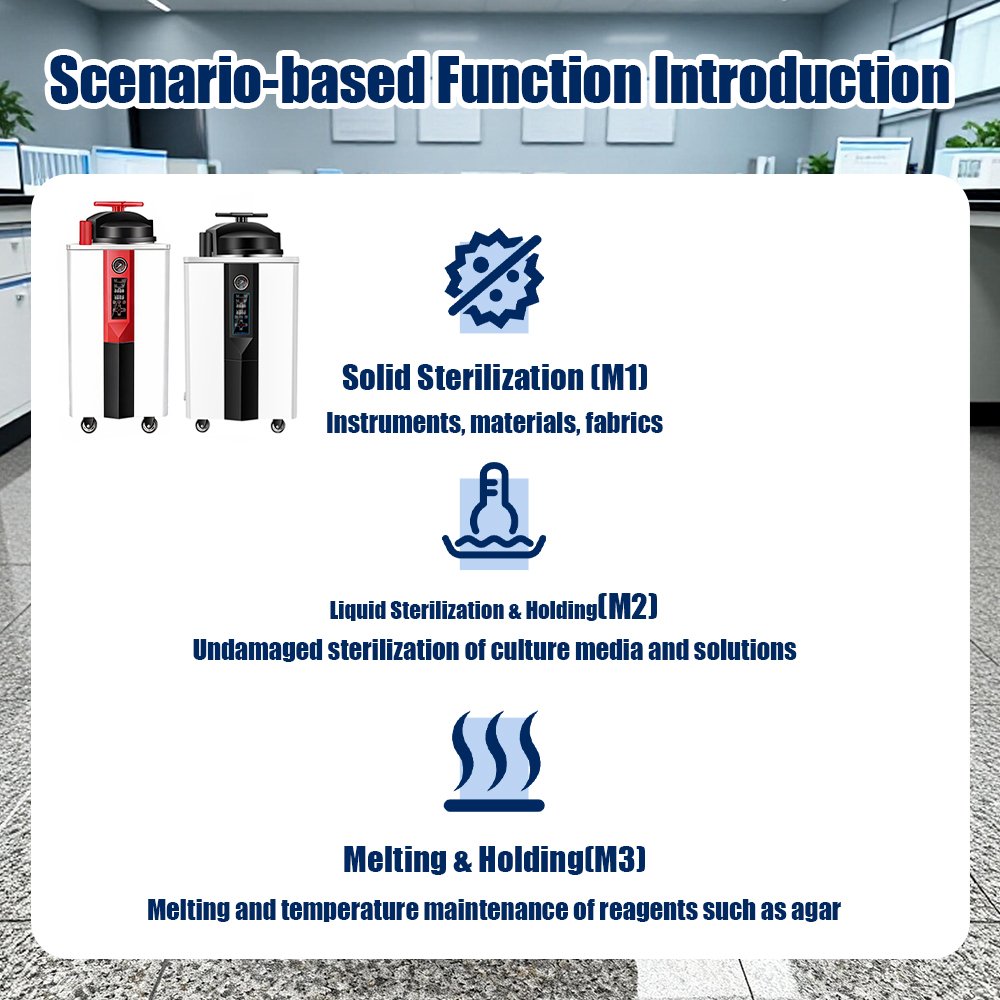

The Handwheel High-Pressure Sterilizer, commonly known as an autoclave, is a critical device in microbiology, medicine, and various industrial fields for achieving complete sterilization. Its primary function is to use saturated steam under high pressure to eliminate all microbial life, including resilient bacterial spores.

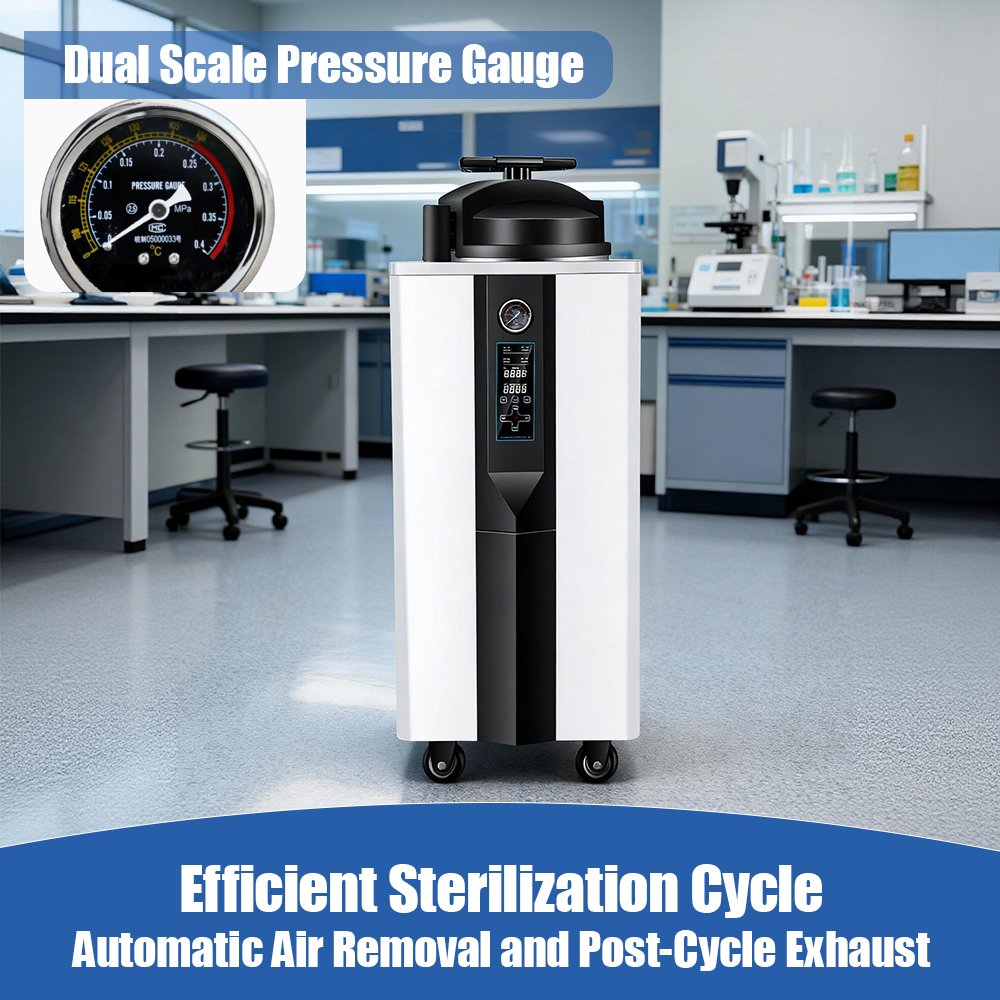

Operation is manually initiated via its defining feature: a sturdy handwheel that securely locks the heavy-duty door, creating an airtight seal essential for building pressure. Users add water to the internal chamber, load it with instruments, glassware, or media, and then heat it. As the water boils, steam displaces the air. The sealed chamber allows pressure and temperature to rise to a standard target of 15 psi and 121°C (250°F). Maintaining these conditions for 15-30 minutes ensures thorough sterilization.

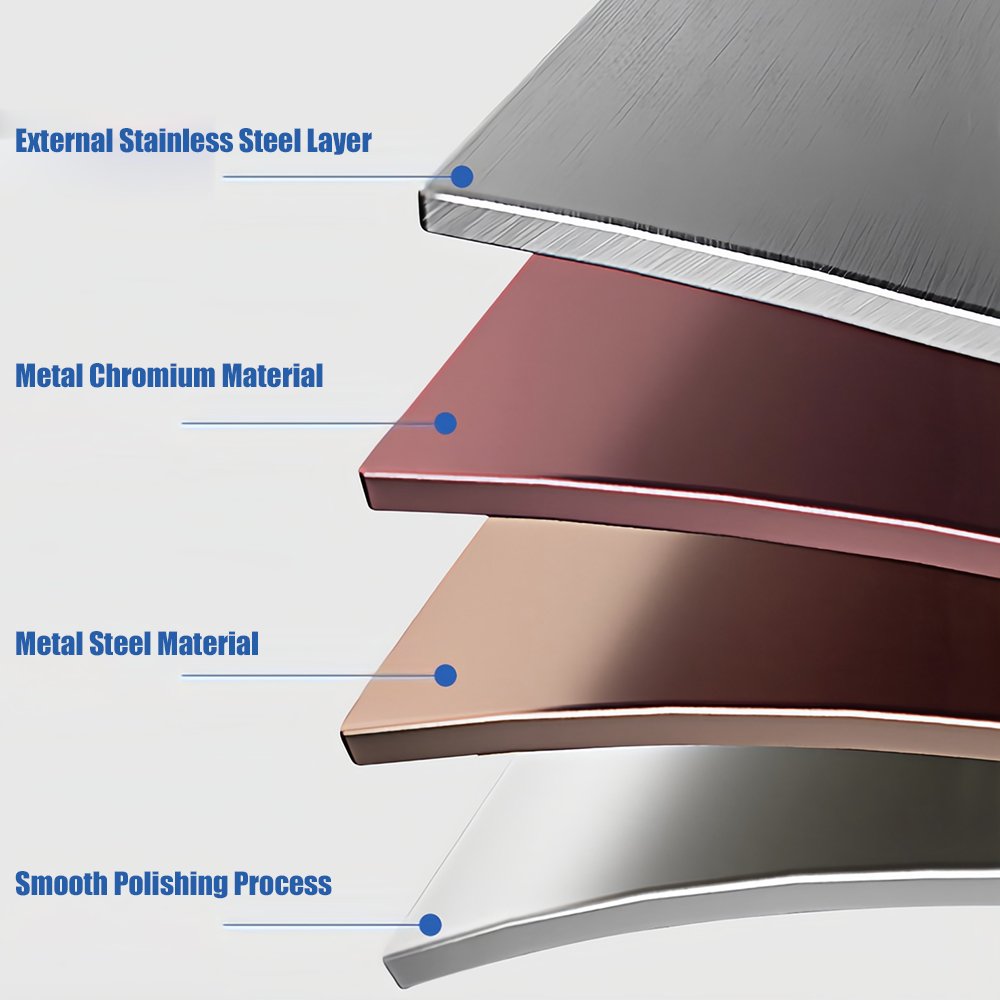

This design offers distinct advantages. The handwheel mechanism provides a reliable, maintenance-friendly mechanical lock without relying on electrical components, making it exceptionally durable. It allows for precise control and a physical sense of security. Built with robust materials like stainless steel, it withstands repeated high-pressure cycles. Key safety features often include a pressure gauge, safety valve, and thermal lock to prevent opening during operation.

While modern autoclaves offer automated cycles, the handwheel type remains valued in many settings for its simplicity, cost-effectiveness, and direct operational control. It represents a foundational and trusted technology for ensuring aseptic conditions in laboratories, clinics, and tattoo parlors worldwide.

“Excellent communication, high quality product. Timely delivery. I have been cooperating for 2 years and am satisfied with the established cooperation.”