- Need Free Consultation ?

(+86) 13145896507

LA258/LA259

High Viscosity Mixer, or Agitator, is a specialized industrial machine designed to homogenize, blend, knead, or dissolve materials with thick, paste-like, or doughy consistencies. These mixers handle substances that do not flow easily under their own weight, such as adhesives, sealants, heavy pastes, polymers, resins, battery slurries, and certain food products like dough or thick sauces.

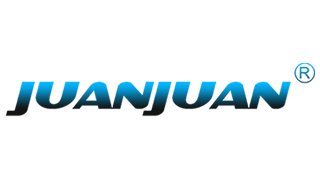

The core challenge in high-viscosity mixing is overcoming immense resistance to movement. Standard propellers fail here. Therefore, these agitators are engineered with robust components: a powerful, low-speed motor with high torque, a heavily reinforced shaft, and specially designed impellers. Common impeller types include heavy-duty anchors, helical ribbons, double planetary blades, and sigmoid/zigma mixers. These designs maximize surface contact, ensure complete sweep of the tank walls, and promote both radial and axial flow to eliminate dead zones.

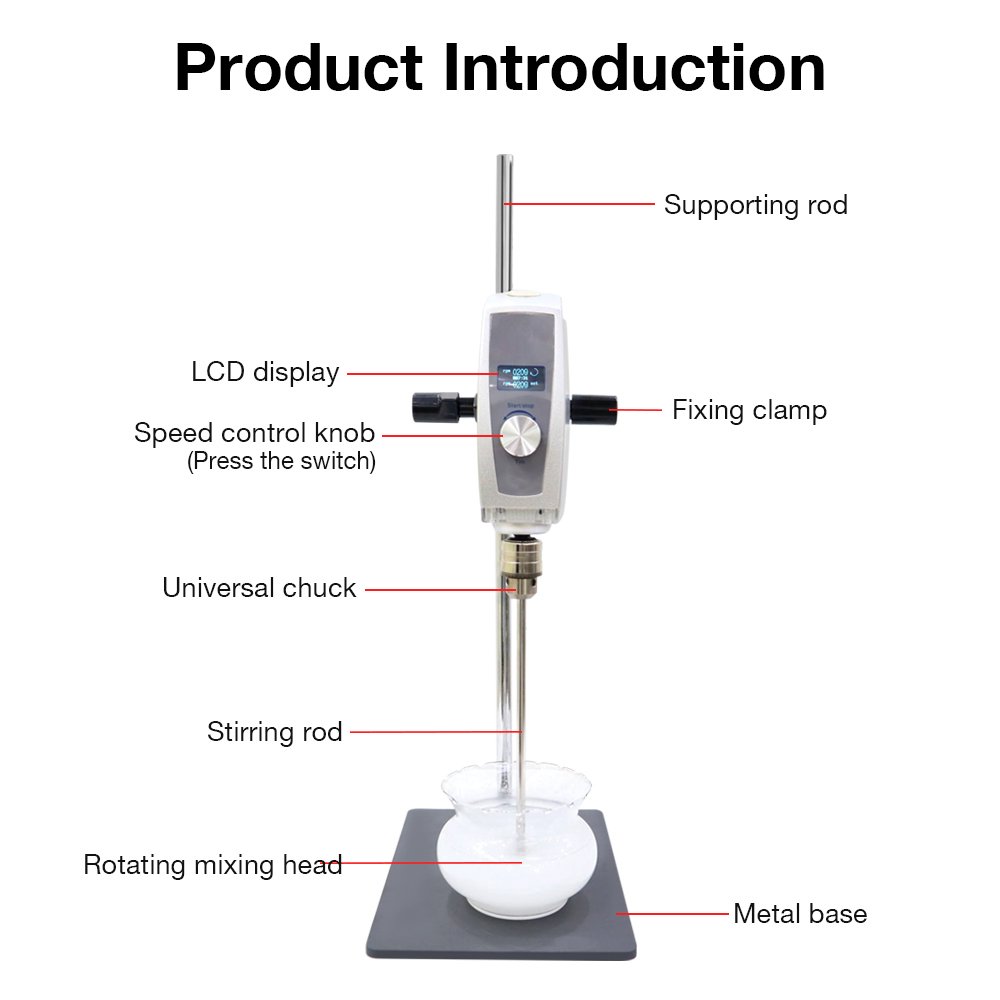

Key features often include jacketed vessels for temperature control, vacuum capabilities for degassing, and advanced seals for containment. They operate in batch or continuous modes, prioritizing uniform shear distribution and precise process control over rapid mixing.

In summary, high-viscosity agitators are essential for transforming resistant, non-Newtonian materials into perfectly uniform, stable, and high-quality end products across critical industries like chemicals, pharmaceuticals, food processing, and cosmetics. Their strength lies in delivering consistent, reliable performance under demanding mechanical stress.

“Excellent communication, high quality product. Timely delivery. I have been cooperating for 2 years and am satisfied with the established cooperation.”