- Need Free Consultation ?

(+86) 13145896507

DF01

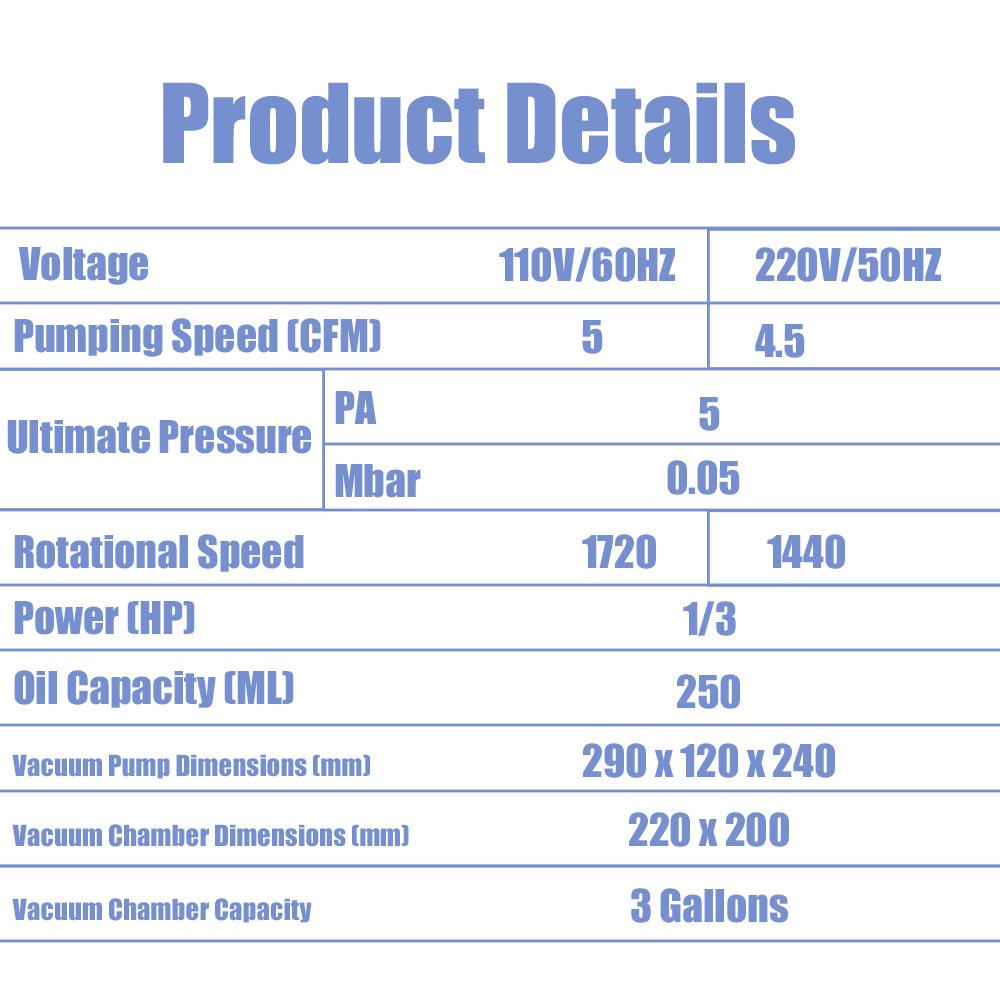

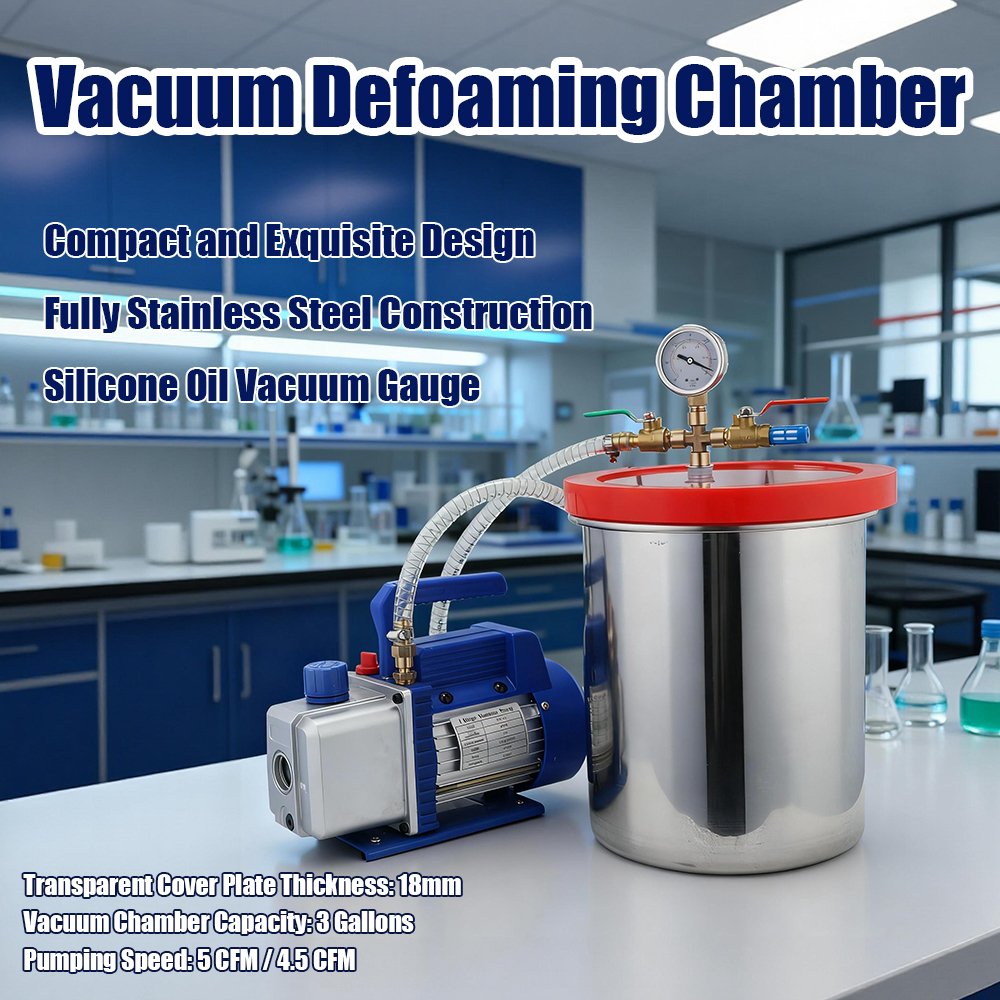

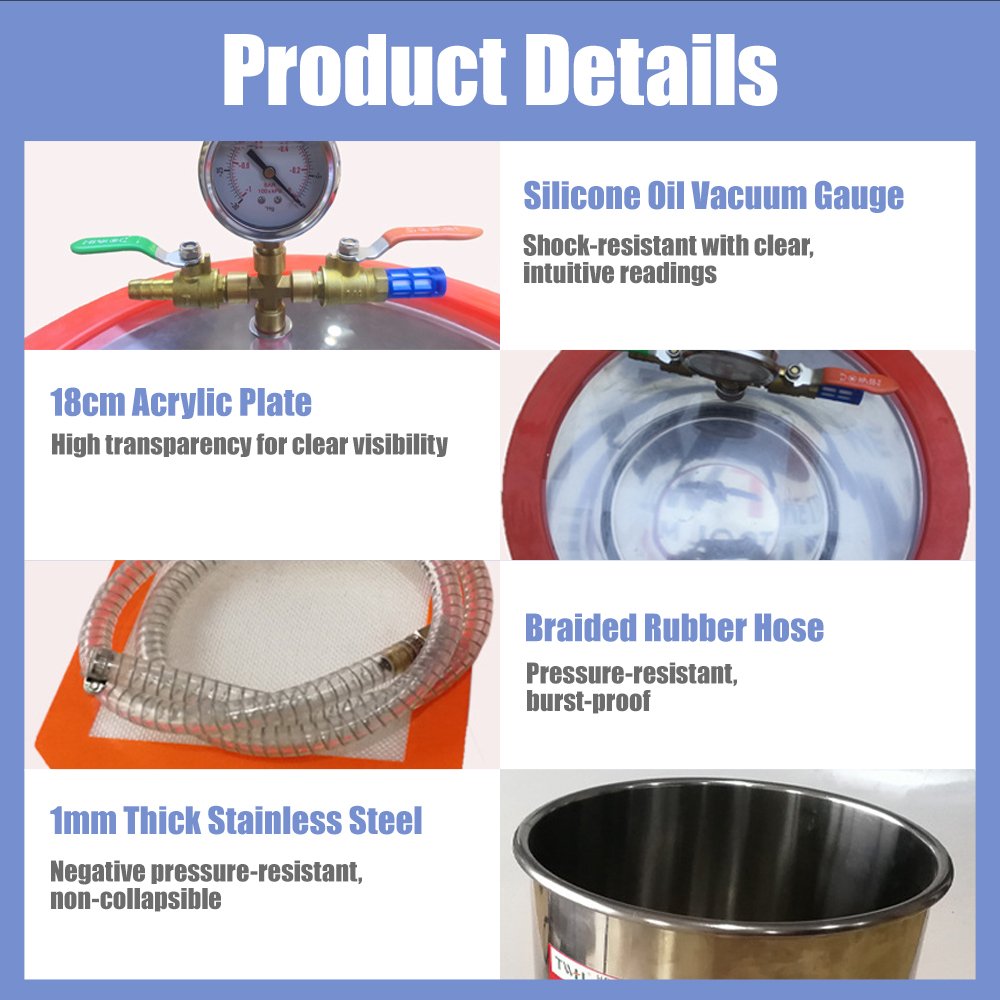

A Vacuum Defoaming Chamber is a specialized industrial device designed to remove entrapped air bubbles and gases from liquid materials, viscous fluids, and semi-solid compounds. It operates by placing the material in a sealed chamber and reducing the internal pressure.

As the vacuum is applied, the air bubbles within the material expand due to the lower surrounding pressure. This reduces their density and buoyancy, causing them to rise rapidly to the surface and burst. The process effectively eliminates voids, ensuring a homogeneous, bubble-free product.

This technology is essential in industries where product integrity, clarity, and performance are critical. Key applications include electronics for potting and encapsulation resins, adhesives and sealants manufacturing, pharmaceuticals and cosmetics for creams and lotions, food processing for sauces and batters, and composite materials production for resins and coatings.

The primary advantages of vacuum defoaming are its efficiency, consistency, and ability to handle sensitive materials without high-shear mechanical agitation, which can damage delicate components or alter material properties. Modern chambers often feature programmable controls, viewing windows, and heating options for viscosity management.

By guaranteeing a flawless, dense final product, vacuum defoaming chambers are indispensable for enhancing quality, reliability, and yield in precision manufacturing processes.

“Excellent communication, high quality product. Timely delivery. I have been cooperating for 2 years and am satisfied with the established cooperation.”